Protective coatings: Stone chipping

Various structural elements made of steel and aluminum, e.g. covers, steering rods and beams, must be protected against corrosion and stone chipping.

Challenge

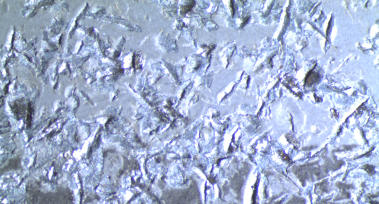

- High load due to stone chipping

- Stone

chipping destroys cathodic dip

painting (Ecoat),

passivation and other corrosion protection coatings.

- Existing spray water and salts lead to corrosion in the damaged areas

- Protective coating must be mechanically resilient during installation, transportation and operation

- No additional energy for drying of the coating.

Solution

- Water-based system that dries quickly at room temperature

- Single-layer system with high yield

- Excellent adhesion under mechanical stress, such as stone chipping

- Firm film during installation due to fast drying

KTL damaged by stone chipping

KTL damaged by stone chipping

Benefit

- Low investment costs thanks to single-layer system with oven-free drying

- Cost-efficient material consumption with selective application

- Low application effort

- Few process steps

- Also a primer for stone chip protection coating

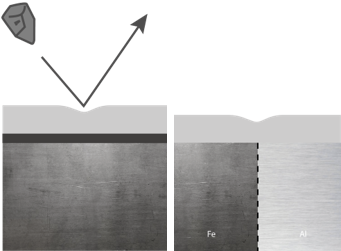

Protection of the primer and base material in the event of stone chipping

Protection of the primer and base material in the event of stone chipping

Application on the car body

Protected underbody of a battery electric vehicle

Possible areas for protective coatings

You may also be interested in these case studies:

Protection of battery system underbodies

Battery boxes are among the most sensitive areas in the vehicle. Their underbodies must therefore not only be protected from corrosion initiated by isolated stone chips, but also withstand constant stress.

Stone chip protection of axle beams

Vehicle axle beams are exposed to high stresses from stone chipping and weathering and must therefore be protected from corrosion.

Underbody protection

The underbody is the area of a vehicle most exposed to weathering and stone chipping and therefore requires long-term flexible protection against corrosion.