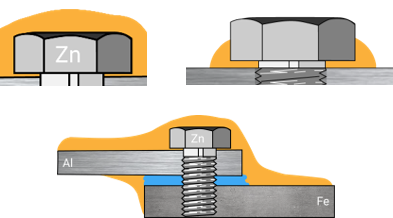

Corrosion protection of joints

Force-fit and form-fit joints are of great importance in automotive engineering, especially in mixed construction, but are susceptible to corrosion and must therefore be protected against moisture at the contact points.

Challenge

- Corrosion protection layer/priming/passivation is destroyed by mechanical processing and joining techniques such as screws, rivets, bolts.

- The expansion behavior of the base material and the bonded joints differ, which can cause the corrosion protection layer to peel off.

- Gaps can form and crevice corrosion accelarates the corrosion of the primary protection layer

- A multi-material mix promotes contact corrosion

Solution

- Application of air-drying waxy anti-corrosion coating with high long-term flexibility.

- Creation of a barrier between water and base material (barrier effect)

- Barrier effect against aggressive media prevents corrosion at the joint

- The material is flexible under thermal and mechanical strain

- If necessary, easy to remove with appropriate cleaners

Damaged and corroded underbody

Precise and true-to-contour wax application due to pulse technology

Benefit

- Universal long-term corrosion protection

- Part function is guaranteed and thus component functionality and safety

- Joints can be easily opened and material residues easily removed (reparability)

Damaged and corroded underbody

Barrier protection for screw connections