Information on the subject of corrosion protection

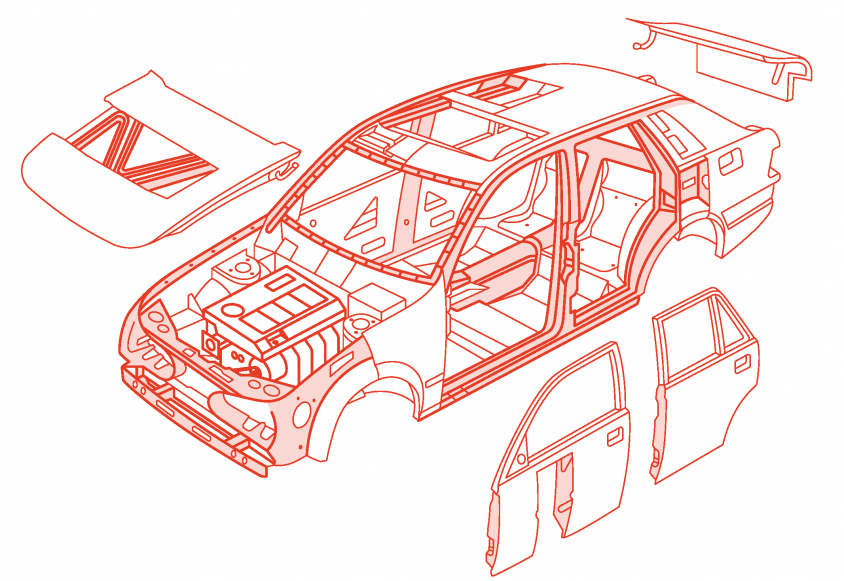

Every motor vehicle has numerous cavities on the body and underbody that are not visible from the outside. They reduce the overall weight of the vehicles and serve to drain off water. To prevent corrosion over time, new vehicles are provided with cavity preservation. This is because rust can cause lasting damage to the substance of the vehicle.

Cavity preservation (HRK) refers to corrosion protection in the cavities of vehicles or machines. Underbody protection (UBS) products are used to ward off corrosive influences in accessible areas.

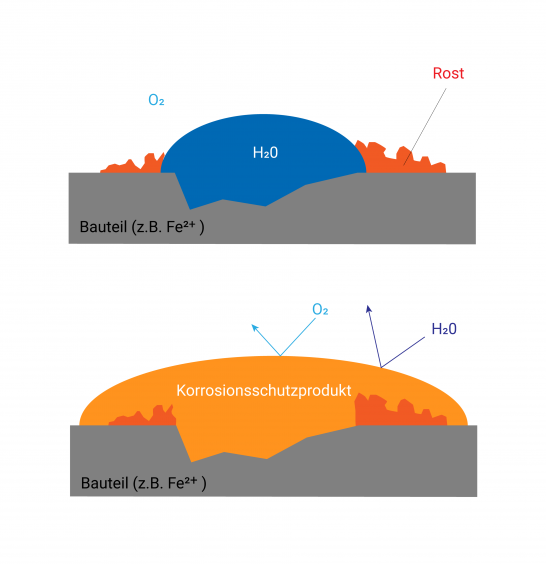

How does corrosion protection work?

Cavity preservation involves applying an anti-corrosion grease or wax to the body cavities. It is important that all affected areas are reached. If rust spots already exist, they are coated by the substances. They thus stop direct contact with oxygen. Further rusting is thus prevented by coating with PFINDER's protective products.

How is optimum corrosion protection ensured?

We offer the optimal cavity protection for each vehicle manufacturer. To ensure this, we can draw on digital cavity preservation simulation. In this way, we help to reduce process costs in the automotive industry and optimize material consumption even before prototype construction or the start of production.

Talk to us!