Protection of battery system screws

Moisture must not be allowed to reach the electrical components in battery systems, so the sealing points must be specially protected.

Challenge

- Bolting and thermal expansion destroys primary protective layer

- Corroding fasteners lead to leakage

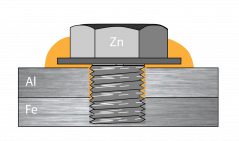

- Multi-material mix promotes contact corrosion

Solution

- Wax-like anti-corrosion coating

- Barrier effect against corrosive media

- Creeping material that penetrates deeply

- Drying at room temperature

- Highest long-term flexibility under thermal and mechanical strain

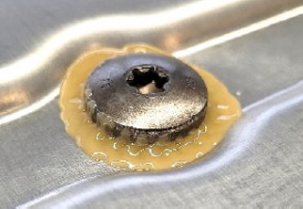

Damaged and corroded underbody

Precise coating of screw heads on batteries

Benefit

- Reliable tightness of the connection

- No complex construction necessary

- Suitable for mixed construction

- Low material costs due to selective coating

- Easy loosening of the connections

- Easy removal of material residues

- Reparability of the battery system

- No energy costs during drying

Damaged and corroded underbody

Protection of the mounting surface of screws