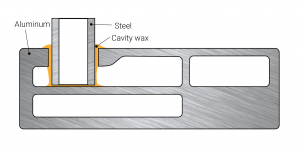

Protection of cavities in battery systems

In battery systems, aluminum extrusions are needed for battery stiffness and are often combined with other materials, which can lead to accelerated corrosion.

Challenge

- Aluminum extrusion combined with other materials

- Material erosion due to galvanic corrosion / contact corrosion

- Different thermal expansions

Solution

- Aqueous wax material drying at room temperature

- Barrier effect against corrosive media

- Low viscosity material creeps into gaps between components

- Material is flexible under thermal and mechanical strain

- Assurance of coating (quantity & quality) by simulation

Damaged and corroded underbody

Protection of a cavity in extruded aluminum profile

Benefit

- Enables mixed construction methods and thus more flexibility in design

- Longer service life and component safety

- Energy and cost efficient solution

- Reduction of costs in the development process through simulation of wax application

- No energy costs during drying